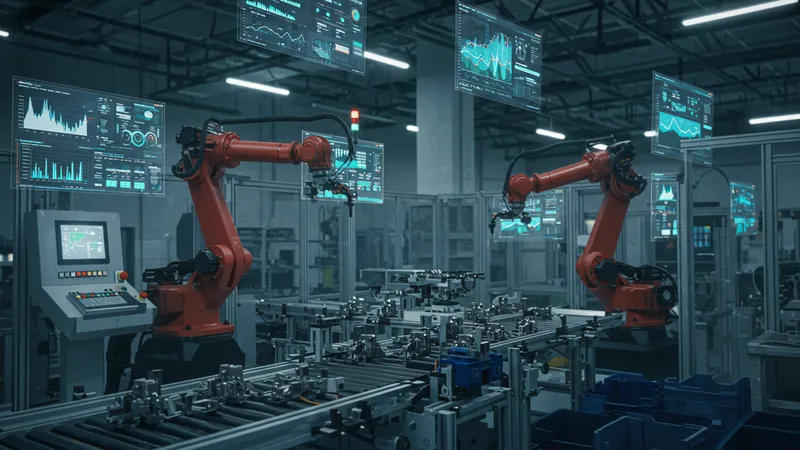

Did you know that over 70% of modern manufacturing industries are now employing advanced automation techniques? Discovering the real impact of this shift will leave you astounded.

As industries rush to adapt to an ever-competitive market, understanding the role of automation in manufacturing has never been more crucial. Those not keeping up could fall behind permanently.

What if I told you that the efficiency gains from automation are reshaping entire economies? In countries like Japan, automation is not just improving output but actually driving cultural shifts in work-life balance. But that’s not even the wildest part…

Consider this: traditional manufacturing jobs are disappearing, yet manufacturers are reporting increased employment. How is this possible? It's about reskilling and redeploying human resources to manage and optimize these advanced systems. But even this transformation holds deeper complexities…

While experts debate this profound industrial change, some companies are making moves that could redefine manufacturing forever. What happens next shocked even the experts...

Automation may seem like a perfect solution, but beneath its sheen lies significant hidden costs. Infrastructure upgrades required for new technology adoption can inflate budget projections by up to 50%. But there’s one more twist…

Labor costs may decrease, but the demand for specialized technicians increases exponentially. Training programs are becoming widespread, adding unexpected long-term expenses for companies. What you read next might change how you see this forever.

Operational downtime during technology integration phases can impact delivery schedules. In some cases, this has led to the loss of lucrative contracts, highlighting an area many businesses fail to anticipate.

Post-deployment, maintaining and updating these sophisticated systems requires continuous investment and innovation, ensuring companies must remain agile. With these insights, are we ready for the future?

The automation boom isn't just revolutionizing processes; it's offering unprecedented competitive advantages. Manufacturers embracing these changes report a 30% reduction in waste. But there's more beneath the surface…

Smarter supply chain efficiencies lead to faster time-to-market, ensuring companies like Toyota stay ahead of global competition. But the real surprise? Innovation is fueling a new era of product development cycles.

Automation is driving rapid product customization capabilities, allowing personalization at scale that was unthinkable just a decade ago. This could completely redefine consumer expectations.

Leading companies adopting automation are not just surviving; they're thriving, with profit margins soaring. This growth is setting new benchmarks, keeping competitors on their toes. But at what cost?

While automation promises perfection, implementation failures can be disastrous. A study showed 20% of companies faced critical errors during their initial rollouts. But don’t let this deter you yet…

Poor integration leads to system downtimes, affecting production and eroding customer trust. Mitigating these risks requires planning and seasoned experts, crucial at each step of deployment.

Security breaches in automated systems have exposed sensitive data, urging stronger cybersecurity protocols. This vulnerability has become a wake-up call to the industry, demanding immediate action.

Despite setbacks, industries are committed to making automation work, iterating processes, and learning from failures. The lessons learned are invaluable, shaping more robust strategies for the future.

While giants like Siemens and ABB dominate headlines, small startups are the unanticipated champions driving innovation. They're developing niche solutions that deliver surprising results…

Startups in Silicon Valley are crafting bespoke AI algorithms focusing on predictive maintenance, drastically reducing machine failure rates with minimal costs. Could these underdogs be the real game-changers?

Some startups have cut energy costs by 25% using advanced sensors and analytics, a feat that could redefine sustainability. They're not just competing; they're reshaping entire markets.

The influence of these nimble players is undeniable, challenging established companies to innovate or risk obsolescence. Their innovative spirit is a testament to the transformative power of automation.

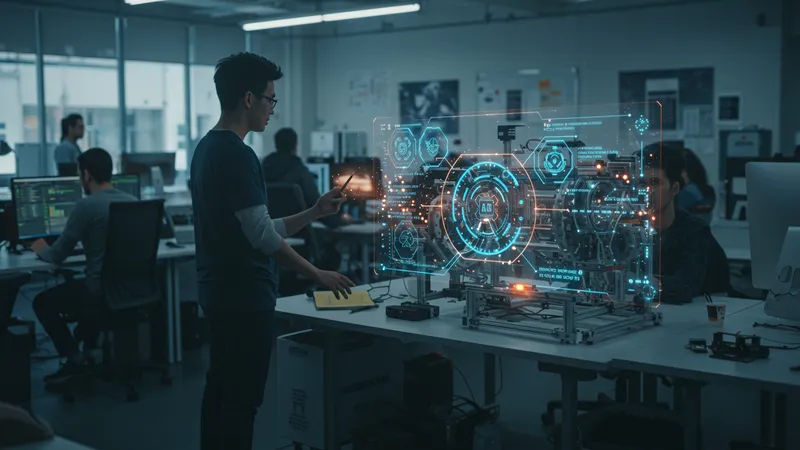

Industry 4.0 demands a workforce fluent in technology and adaptability. This evolution is shifting skillset paradigms, from manual labor to tech-savvy roles. But there's more to this transformation…

Global initiatives are now focusing on upskilling workers to bridge automation gaps. Companies that invest in employee development see a significant increase in productivity and retention rates.

Educational institutions have started collaborating with industries, redesigning curricula to meet the demands of tomorrow. This collaboration will be vital in sustaining future industrial growth.

The shift towards tech-oriented roles isn't just reshaping skillsets—the perception of manufacturing is evolving, making it an attractive career path for the tech-centric youth.

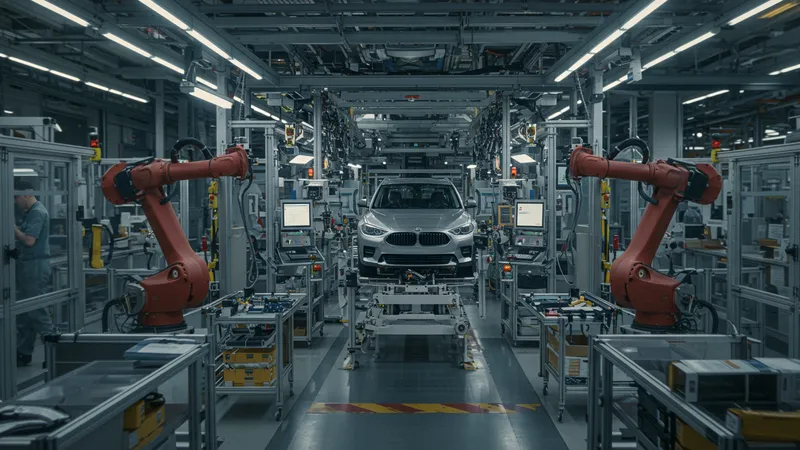

Innovators like BMW and Tesla are showcasing remarkable automation success stories globally. Their journeys have been filled with lessons and triumphs in equal measure…

BMW's smart factory in Germany is a paragon of efficiency, intertwining human expertise with robotic precision, cutting production times significantly. But there’s more to explore here.

Tesla’s Gigafactories employ cutting-edge automation, setting a new standard for electric vehicle manufacturing. Their unprecedented speed in responding to market demands is a case study in itself.

These stories illuminate how automation is more than a buzzword—it's an evolutionary leap that's realigning industry benchmarks and expectations across the board.

Automation isn't just boosting efficiency; it's paving the way for sustainable practices. Companies are achieving up to 20% reduction in carbon footprints. But here’s an unexpected benefit…

Advanced automation reduces waste and optimizes resource utilization, contributing to eco-friendly manufacturing processes—even with higher production demands.

Renewable energy sources are being harnessed more effectively, thanks to automated systems, leading to a surge in sustainable business practices across industries.

These developments are not just good for the planet—they’re also becoming essential for businesses looking to comply with new international environmental standards.

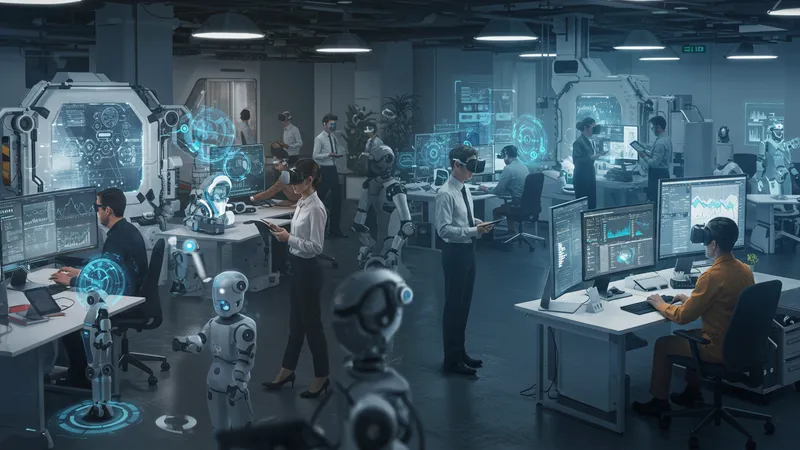

Beyond industry walls, automation is influencing cultural shifts, fostering a new work-life balance model. The blend of remote and in-person tasks is gaining ground, providing flexibility like never before.

Employees report increased satisfaction with flexible schedules, as automation takes on monotonous tasks. This shift is redefining job roles and worker satisfaction, but there’s more under the surface…

With fewer hours tied to the traditional office, creative and innovative outputs have surged, showcasing human potential when unburdened by repetitive tasks.

This cultural transformation heralds an era where the focus on work-life harmony is not just theorized—it’s being actively realized through automation’s influence.

The upfront costs of automation might seem formidable, but the financial returns can't be ignored. Some companies report ROI improvements exceeding 200% in a year. But there’s another gain…

With increased efficiency and reduced operational costs, companies have been able to redirect savings into research and development, spurring further innovation.

Investors are increasingly drawn to firms embracing automation, recognizing the long-term strategic benefits beyond immediate cost savings.

This financial boom is not just reshaping corporate balance sheets—it’s altering the global investment landscape, earmarking automation-savvy firms as the future’s darlings.

Contrary to fears of rampant job loss, automation is creating new roles, particularly in tech maintenance and management. Employment landscapes are evolving in unexpected ways…

Companies are realigning roles, ensuring a balance between workforce reduction in manual tasks and the creation of skilled tech positions.

The paradox of job automation is surprisingly fostering entrepreneurship, with small businesses empowering specialized service offerings in the automation domain.

This dynamic is proving that, with strategic adaptation, job markets can not only withstand automation's rise but thrive alongside it, reshaping employment paradigms for the better.

On the horizon, groundbreaking innovations threaten to redefine automation again. Quantum computing and AI promise levels of efficiency previously unimaginable, yet their integration holds surprise potential.

These emerging technologies are unlocking capabilities such as predictive analytics that foresee machine failures before they occur, minimizing downtime.

3D printing integrated with automation is set to revolutionize production models, offering versatile, in-house manufacturing capabilities tailored to bespoke demands.

The pathway to these innovations is filled with promise and complexity, urging industries to stay vigilant as they chase the edge of tomorrow's technological frontier.

Automation demands a reevaluation of organizational structures, prompting industries to restructure hierarchies to align with new efficiencies. But the transformation offers added benefits…

Flattened hierarchies foster better collaboration and innovation, reducing decision-making times and enhancing responsiveness to market changes.

Streamlining roles not only optimizes cost structures but empowers employees, encouraging a culture of innovation and engagement throughout the entire organization.

This systematic realignment is not just about efficiency—it's redefining the corporate culture to thrive in an accelerated automated world.

In the automated landscape, the synergy between human operators and machines is crucial. Collaborative robotics are at the fore, achieving productivity increases of up to 50% while sharing tasks.

Robots now assist rather than replace, allowing human workers to focus on higher-order tasks, creating a harmonious balance that maximizes potential and minimizes redundancy.

However, ensuring seamless collaboration requires ongoing training and recalibration of processes, emphasizing the need for continuous learning in dynamic environments.

This collaboration is creating unique work environments where humans and machines integrate harmoniously, setting new benchmarks for productivity and workplace satisfaction.

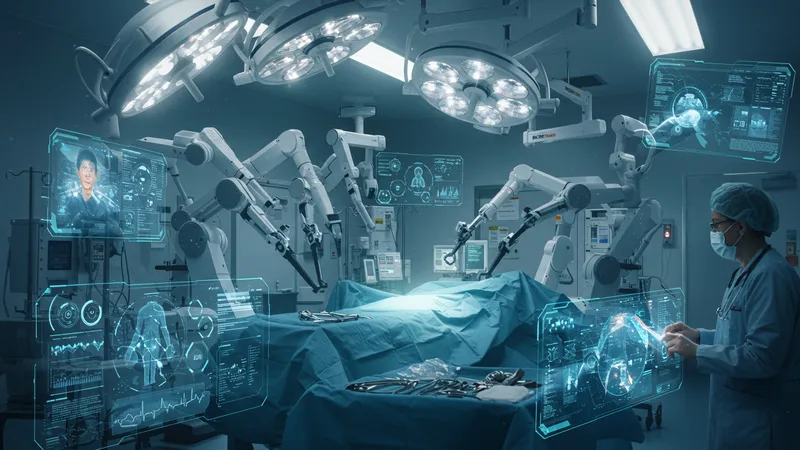

As manufacturing masters automation, other sectors are next in line. From healthcare to finance, industries are preparing to embrace automation’s wide-reaching impact on efficiency and service.

In healthcare, automation in diagnostics and surgery is reducing error margins and improving patient outcomes, but challenges remain in implementation.

The finance sector is seeing transformative impacts as automated systems handle complex data analysis, paving the way for more dynamic market strategies.

This cross-industry ripple effect showcases automation's potential to redefine business models across diverse sectors, reshaping foundations worldwide.

This transformation in industrial machinery speaks volumes about the future—an era dominated by a harmonious interplay of humans and automation. But the most profound twists are yet to unfold…

As automation becomes the standard, sharing these insights can spark discussions and innovations that shape our collective future. Don’t keep this knowledge to yourself—share it widely, explore further, and be part of this exciting evolution.