Did you know that modern industrial machinery is transforming industries at an unprecedented pace? What was once impossible is now a reality, thanks to groundbreaking technology that defies convention.

As industries race to adapt, staying informed about these innovations is crucial. The potential for increased efficiency and reduced costs means that now is the time to engage with these technological advancements.

Industrial machinery is not just about massive structures and loud noises. Recent developments, like using biomimicry in design, have taken efficiency to entirely new heights. Imagine machinery that operates as seamlessly as nature itself. But that's not even the wildest part…

On the energy front, we're witnessing an influx of machines harnessing renewable energy. These are not only greener but are proving to be more cost-effective over time. Yet, the true revolution lies beneath the surface and it's waiting to astonish even the skeptics…

What happens next shocked even the experts: could your industry be next in line for a game-changing upgrade? The innovations coming out of this sector promise to rewrite the rules and elevate standards across the board. Prepare to dive into the machines that are not just changing the way we work, but also how we think about possibilities.

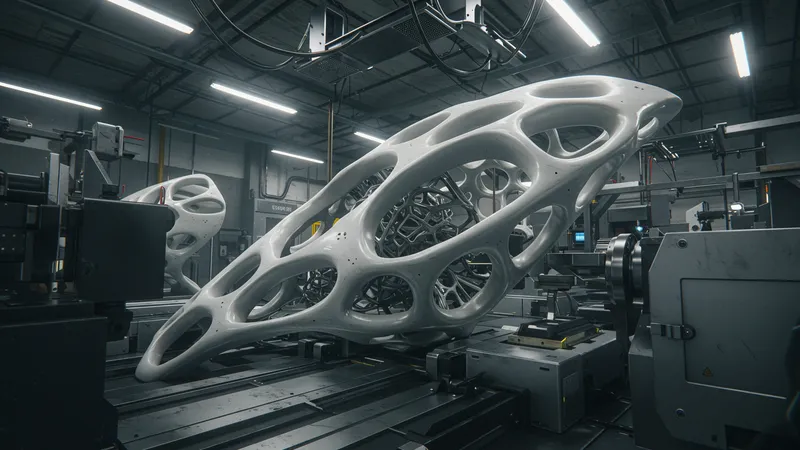

Biomimicry in industrial machinery is lending an unexpected hand in design. By replicating nature's time-tested patterns, engineers are crafting machines that are more efficient and durable. These bio-inspired designs lead to more seamless integration into existing workflows. But there's one more twist…

In one groundbreaking development, factories are adopting new machine designs modeled after the efficiency of a bird's bone structure, resulting in unprecedented strength-to-weight ratios. These advancements are empowering heavy industries to redefine their production capabilities. What you read next might change how you see this forever.

Beyond just structure, biomimicry is influencing how these machines process energy and information. Just as plants efficiently harness sunlight, machines are beginning to do the same with solar technology. The practical applications are making waves in energy-dependent sectors. But the real shock lies in how versatile and adaptable these machines have become…

These innovations aren't just abstract concepts; they're already being put to work in sectors like automotive and aerospace. Imagine planes and cars taking pointers from birds and fish, not just in aerodynamics but in energy efficiency too. The future is not just coming—it's here, creating industries of possibilities you never thought possible.

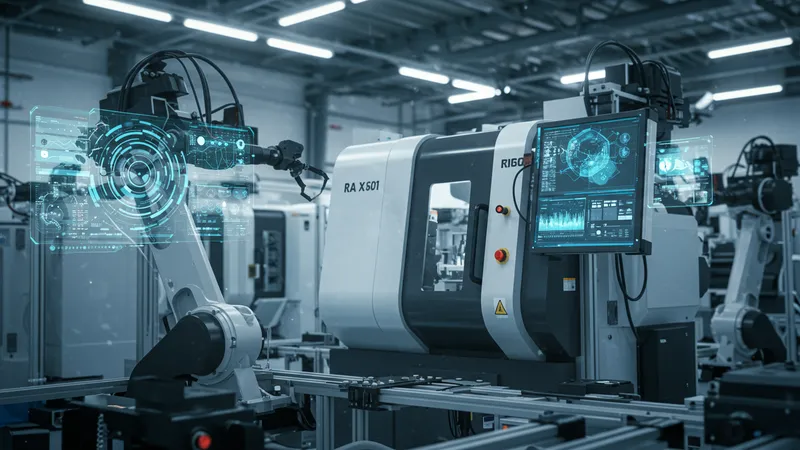

Artificial intelligence is making strides in industrial machinery, transforming previously cumbersome operations into streamlined processes. By implementing machine learning algorithms, these machines can now self-diagnose and correct errors with minimal human intervention. But the story doesn't end there…

AI allows machines to adapt in real-time to varying conditions, learning and evolving like a living organism. This adaptability is minimizing downtime and enhancing productivity, enabling factories to operate at never-before-seen levels of efficiency. But what does this mean for the human workforce?

The precision of AI-driven robotics in sensitive tasks surpasses human capabilities, leading to safer work environments and the ability to handle hazardous tasks. Yet, the most profound impact of AI is how it's challenging us to rethink the role of humans in industries altogether. The implications might just surprise you.

Despite fears of job loss, AI is creating new roles in programming, maintenance, and oversight, emphasizing the synergy between human creativity and machine efficiency. As the line between human and machine work continues to blur, a new industrial era is upon us, with opportunities that were once the stuff of dreams.

Renewable energy is reshaping how industries power their machinery. By harnessing solar and wind power, companies are not only cutting costs but drastically reducing their carbon footprint. This is not merely a trend—it's becoming the new standard. But hold on, there's another layer to uncover…

The integration of renewable energy is making machines sustainable and more autonomous, allowing for operations in off-grid locations. This ability to circumvent traditional energy infrastructure is revolutionizing accessibility and functionality. What does this mean for remote regions and developing economies?

These greener machines promise significant environmental benefits without compromising on power or productivity. Sectors like mining and agriculture are already reaping the advantages of deploying such technology, leading to a lush future where machines work hand-in-hand with nature rather than against it. But there's an unexpected ripple effect…

Transitioning to renewable resources isn't merely about power. It's about empowering industries to rethink production cycles and supply chain logistics. As machines become more sustainable, so too does the demand for sustainable materials and practices, sparking a comprehensive green revolution throughout industries worldwide.

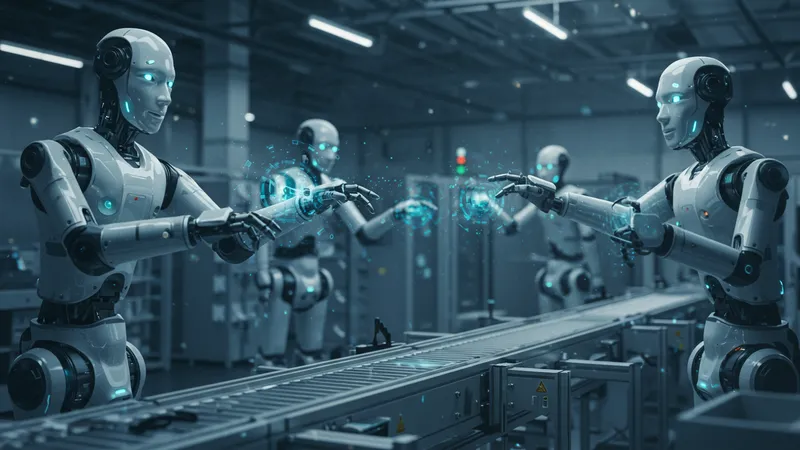

Robotization in production lines has advanced beyond simple task repetition. Today’s robots are designed with cognitive capabilities, allowing for complex problem-solving and multitasking. But this is only the beginning…

Utilizing sophisticated sensors and AI, robots can now engage in human-like interactions, performing tasks with an unprecedented level of finesse and accuracy. As these advancements continue, traditional production is being turned on its head, resulting in customizable, efficient, and precise outputs that were unimaginable before.

Incorporating robotics into production processes is improving safety standards by reducing the need for human exposure to hazardous environments. Yet, the biggest change might be how robotics are enabling a more versatile approach to manufacturing, accommodating rapid shifts in consumer demand and trends. But here's the catch…

The implications extend beyond mere efficiency. As robots play a larger role, there's a growing necessity for a workforce skilled in robotics and analytics. This paradigm shift is forcing industries to reconsider their approach to workforce training and development. But could this transformation signify something even more profound for future generations?

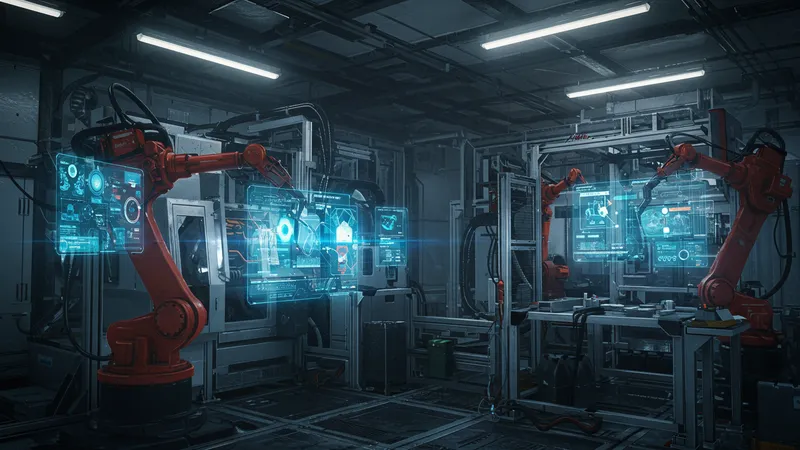

The Internet of Things is facilitating an unprecedented level of connectivity within industrial machinery. Machines now communicate seamlessly, sharing data and insights to optimize processes in real-time. But there’s an unexpected twist…

This interconnectivity allows for predictive maintenance, significantly reducing downtime and maintenance costs. Before a breakdown occurs, machines can alert technicians, leading to proactive solutions and uninterrupted production cycles. But that's just one facet of its potential…

With IoT, factories are evolving into smart ecosystems where every component interacts harmoniously. This leads to a more responsive industrial process that adapts dynamically to shifts in demand or supply chain disruptions. Could this seamless integration redefine the industry's very fabric?

As IoT becomes the norm, security and data management emerge as paramount. Industries are now grappling with securing vast amounts of data generated by these interconnected systems. The stakes are high, but the rewards lie in fostering a smarter, more connected industry landscape that promises resilience and adaptability.

Autonomous vehicles are revolutionizing the logistics sector by reducing human error, optimizing delivery routes, and cutting operational costs. But these are just the tip of the iceberg…

With the adoption of these vehicles, supply chains are becoming more efficient and resilient. Automated fleets are setting new standards in delivery speed and reliability, enabling businesses to exceed customer expectations consistently. What's the knock-on effect for global logistics?

Autonomous technology also opens doors for improved environmental practices by facilitating optimized driving patterns that conserve fuel. While the direct benefits are notable, the real impact could be seen in how this tech spurs innovation throughout logistics and beyond. But there's a strategic dimension to consider…

The transition to a self-driving fleet requires a complete overhaul of current logistics infrastructures and systems. Companies must be agile and forward-thinking to keep pace with these changes, but those who do are likely to lead a global transformation that echoes across all sectors they touch.

3D printing is revolutionizing the way industries approach manufacturing by enabling rapid prototyping and on-demand production. But this innovation goes even deeper…

The ability to produce components in-house reduces reliance on complex supply chains, decreasing lead times and costs significantly. This is not a passing trend but a burgeoning pillar of modern manufacturing. But why stop at components?

With advances in materials and technologies, 3D printing is pushing the boundaries of what's possible, from customized tools to full-scale structures. Industries from aerospace to healthcare are discovering unexplored potential in this technology. But what are the limits, if any?

Embracing 3D printing allows for a more sustainable approach by minimizing waste and using recycled materials. As more industries incorporate this technology, the collaborative efforts drive further advancements in 3D printing capabilities, promising to fundamentally alter the manufacturing narrative.

Nanotechnology is a game-changer in industrial machinery, bringing unfathomable precision and efficiency to even the smallest components. Big things come in small packages, correct? But that’s only scratching the surface…

By manipulating materials at the molecular level, industries can craft parts that are stronger, lighter, and more resilient than their traditional counterparts. This precision paves the way for astonishing developments in sectors such as defense and automotive. What does this mean for future products?

The use of nanomaterials also lends itself to innovative energy solutions, creating more efficient batteries and power systems. But the true potential lies in how these nanotechnologies integrate into our everyday industrial machinery. Are we at the start of a microscopic revolution?

Industries must consider the sustainability and ethical implications that accompany nanotechnology's rapid adoption. While the possibilities are limitless, responsible deployment is crucial to ensuring these advances benefit society as a whole. This pivotal moment might shape years of industrial evolution.

As we stand on the brink of industrial transformation, these innovations are not merely about machines but a rethinking of how industries should function and thrive. In an age where progress moves faster than ever, staying informed and adaptable is crucial for success. Embrace the change, share the knowledge, and be part of this exciting leap into the future. The world of industrial machinery is reshaping before our very eyes—are you ready to take your place in this evolving narrative?